MILESTONES

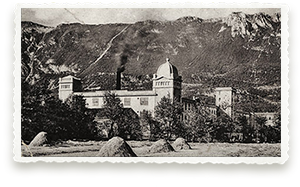

Production first started in the Imperial Private Mechanical Spinning Mill in Ajdovščina, equipped with “Mule Jenny” self-actors. Up until the beginning of the 19th century wool and cotton were still processed by hand. The first machine to spin cotton was only invented in 1764, even though it was still operated by hand. The so-called self-actors came later and were the first machines to spin wool and cotton automatically. Since their invention, production of textiles blossomed and Tekstina was among the first plants to boast this breakthrough innovation.

1828

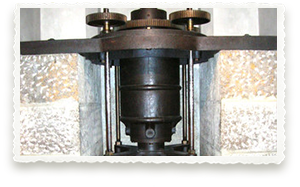

The waterwheel was replaced with a newly developed Fourneyron turbine constructed in Paris. At that time, this type of turbine was at the very pinnacle of technological advancement, being invented by Benoît Fourneyron only two years prior. This type of turbine replaced a vertical waterwheel with a horizontal one, increasing the number of rotations to a previously unimaginable 2,300 rotations per minute. The new turbine generated 60 horsepower and was responsible for a major increase in production.

1839

Installation of the first steam engine. Running the mill on waterpower from a turbine was extremely successful, however it required that the factory be positioned next to a stream. Introduction of a steam engine abolished this need, and the factory was free to move away from the water source. Also, power generated from water was unreliable, as it was dependant on the amount of water in the stream, which fluctuated with the seasons. Steam engines were an extremely important element of the industrial revolution and Tekstina was successfully taking advantage of the benefits it brought.

1850

After the II. World War the factory started to operate again after a brief suspension, which saw parts of the factory be used as a warehouse, barracks, and horse stables. What is more, after the war some of the facilities were sectioned and dedicated to the establishment of another hugely successful industrial endeavour, Fructal Ajdovščina. Nevertheless, despite historical circumstances working against it, Tekstina started with full operations again in 1948.

1945

Less than ten years later, Tekstina was richer for a brand-new paint room and boiler room. The development and accelerated growth that the company was experiencing after the war was beginning to bear fruit. The new building was also boasting a 46m tall chimney, which was the highest chimney in the valley at the time.

1954

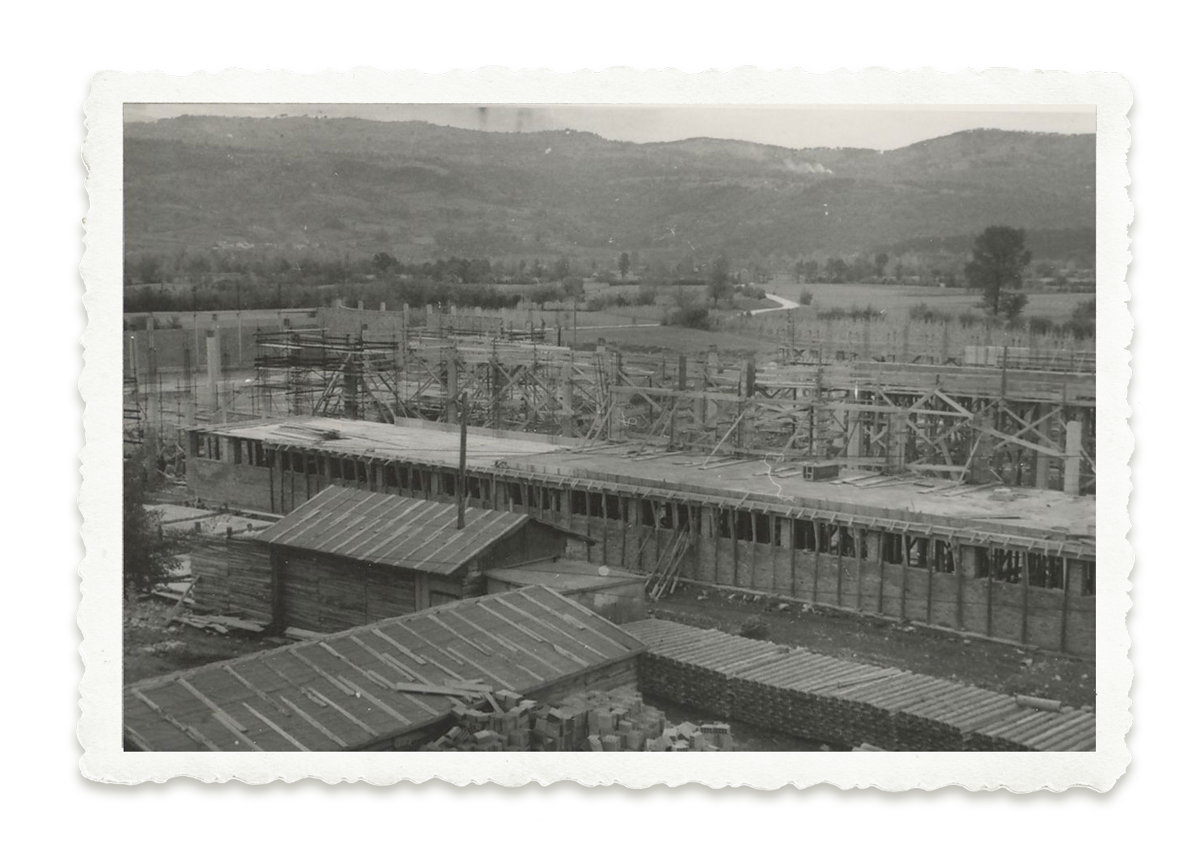

Construction of a new spinning mill. As the old spinning mill building has burned down several decades prior, and as the factory was experiencing steady growth in production, sales and number of employees, a new building for the spinning mill was built in 1960. This building marks the beginning of the times when Tekstina transformed into a contemporary fabric producer.

1960

We are very proud of our investment into a new rotary printing press. We have invested a lot of our efforts into optimizing the printing process. We have managed to define the ideal pressure of the dyeing cylinder onto the textile. This allows us to claim we can now produce some prints that are among the best in terms of durability and precision.

2015

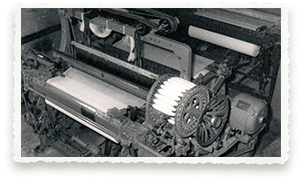

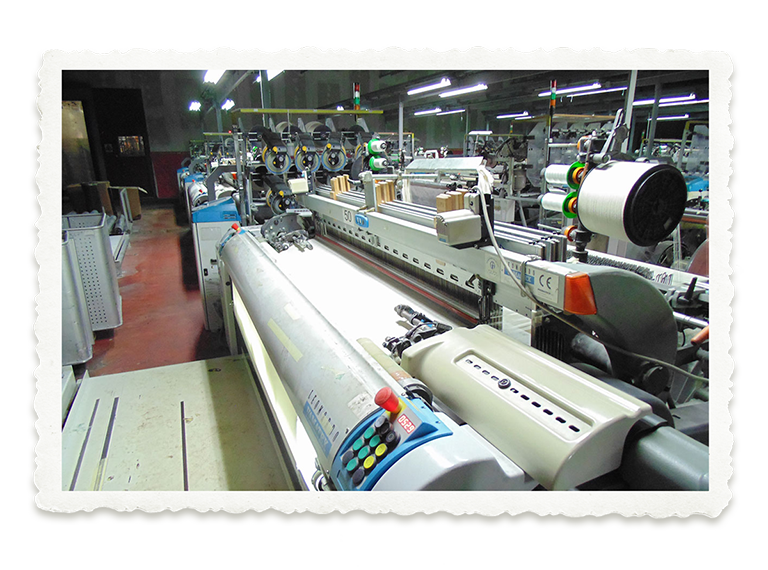

Our weaving mill is a modern environment where creativity and innovation can benefit from the decades of experience. Our achievements in the areas of sustainability and printing innovation have proven once again that we are among the best fabric producers in Europe.

2016

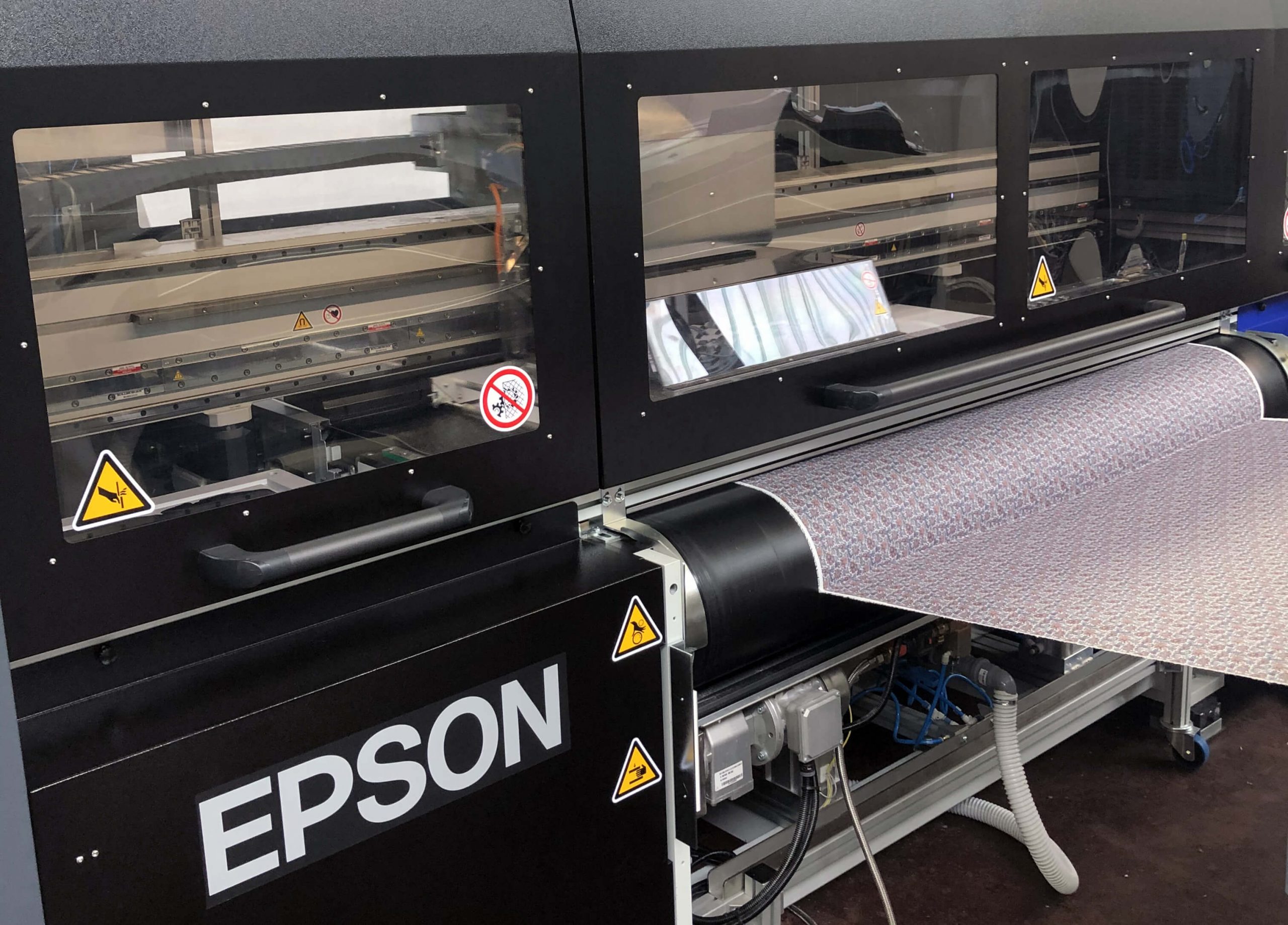

The printing technology used at Tekstina is updated regularly to include the latest solutions and innovations. The digital fabric printing machine Monna Lisa® complements the collection and provides extreme uniformity of geometric patterns, precision printing and use of different types of ink, depending on the textile used and the desired design. It allows high-quality printing on textiles of a thickness up to 10mm and 1800mm in width

2021

Two new state-of-the art weaving machines are added to Tekstina’s wide portfolio. Itema R95002 air-jet machine is an exciting new asset to Textina, as it is extremely efficient and fast, while Itema R95002 rapier machine decreases the production costs considerably. Its sophisticated software also allows for the production of thicker fabrics and more demanding projects.

2022